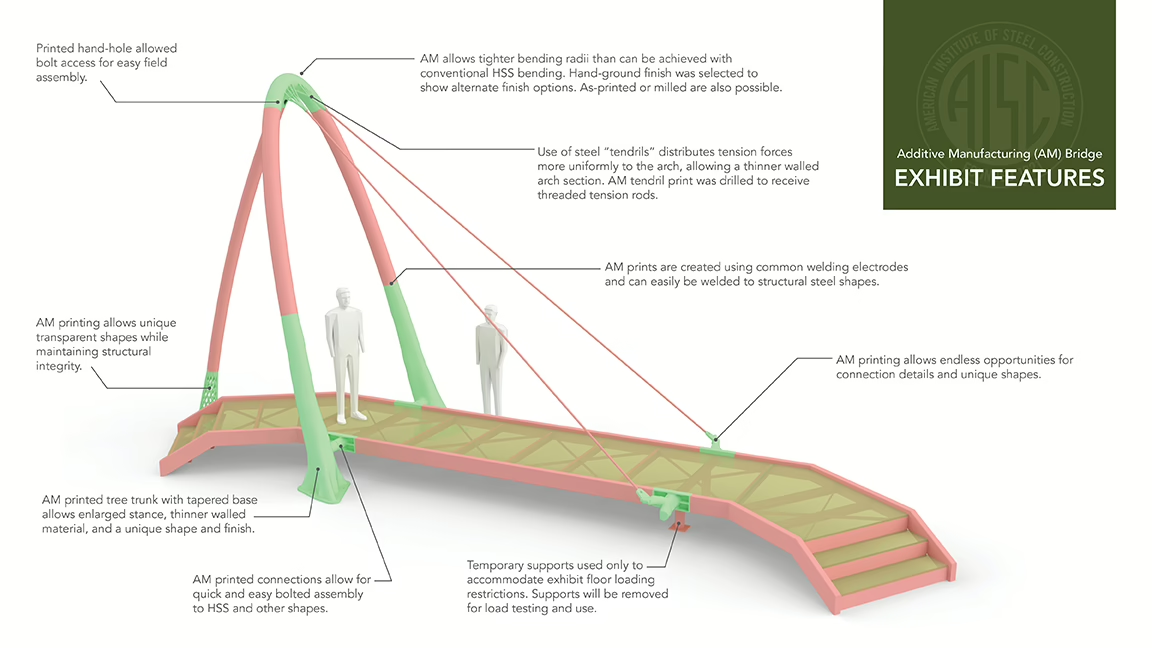

Partnering with the American Institute of Steel Construction (AISC) and other industry leaders, MKA designed a 50-foot-long, first-of-its-kind pedestrian bridge to showcase the possibilities of a new technology in the steel industry: steel additive manufacturing.

Steel additive manufacturing—or 3D printing with steel weldment—has the potential to be a game-changer in the steel industry:

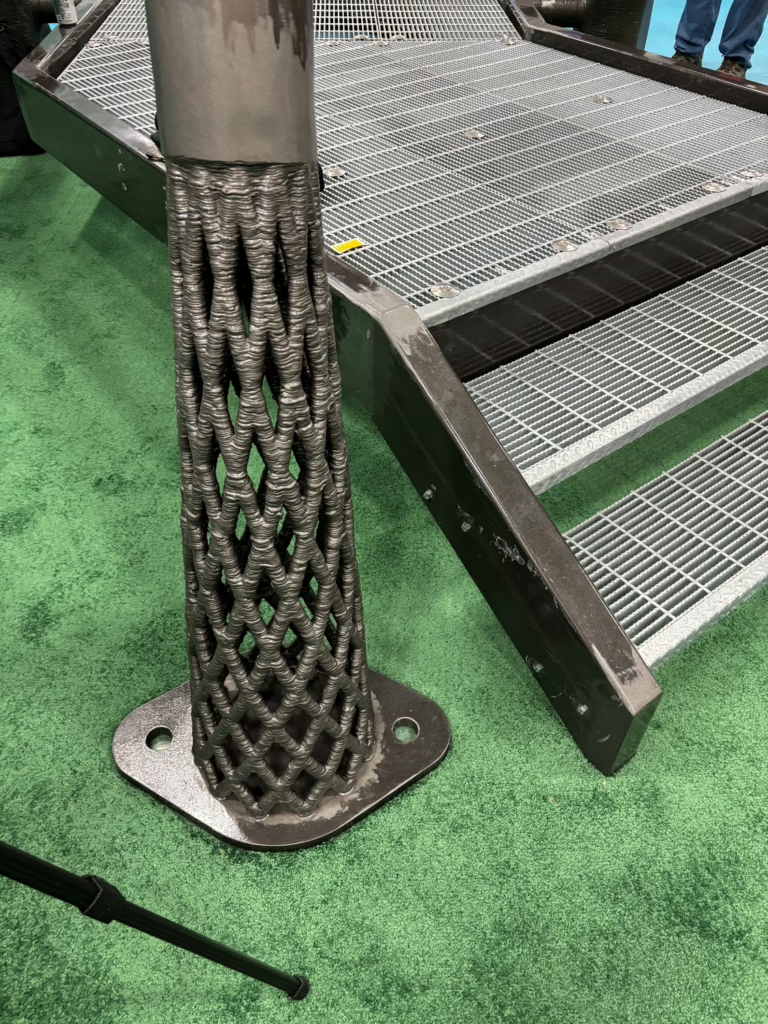

- Custom steel shapes can now be printed in virtually any shape to create desired aesthetics.

- Complex geometries can be printed to achieve geometries and connections that could not otherwise be achieved.

- Standard structural shapes like hollow structural sections can be seamlessly combined and connected to 3D-printed steel components.

- Unique structural shapes can be analyzed, optimized, and printed so that only the necessary material is provided, reducing the overall amount of material used.

Upon completion, the bridge was showcased at NASCC ‘25 in front of almost 7,000 attendees. It was then shipped to the Georgia Institute of Technology in Atlanta for load testing. The tests will confirm the bridge’s unique printed steel shapes have the structural capacity determined through a finite-element analysis.

Additive manufacturing technology has broad applications and opens doors for endless possibilities of unique shapes and complex geometries in future steel bridges and buildings.

Want to Learn More?

Additive manufacturing in combination with traditional structural steel shapes can be a powerful tool for architects and engineers. Contact MKA President David E. Eckmann, PE, SE, FAIA, or MKA Senior Principal Robert Baxter, PE, SE, to learn more.